In the realm of chocolate production, precision and efficiency are paramount. One of the key devices enhancing these aspects is the

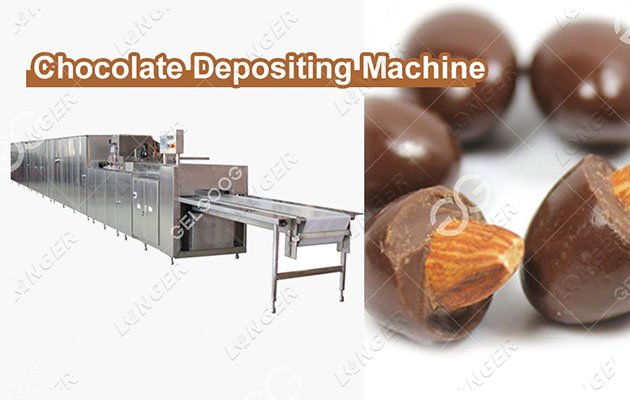

Chocolate Depositing Machine. This specialized equipment is designed for accurate dosing and depositing of chocolate, capable of handling single-color, dual-color, and filled chocolates.

Overview of Chocolate Depositing Machines

The Chocolate Depositing Machine operates through a system comprising an electric motor, gearbox, indexing mechanism, and sprockets for rotational movement. A custom chain plate system guides the molds along rails, ensuring precise positioning. Control is achieved using proximity switches for motor activation and frequency-controlled (servo) motors for precise dosing, with the stroke of the servo motor determining the amount of chocolate dispensed.

Advantages and Features

● Structural Simplicity: Simple design facilitates ease of operation and maintenance.

● Accurate Dosing: Ensures precise chocolate quantities with each deposit.

● Reliable Mold Positioning: Consistent positioning of molds for uniform chocolate shapes.

● High Efficiency for Filled Chocolates: Capable of accommodating up to 15% filling volume, ideal for various mold types.

● User-Friendly Operations: Low labor intensity and straightforward operation enhance usability.

● Hygienic Standards: Meets hygiene requirements with features like automatic molding, depositing, and thorough vibration.

The Chocolate Depositing Machine stands out in chocolate manufacturing for its efficiency, precision, and ease of use. Whether for small-scale artisanal production or large-scale industrial applications, this equipment ensures consistent quality and operational reliability, meeting the diverse needs of chocolate producers worldwide.

EN

EN

Release Lime: 2025-03-27

Release Lime: 2025-03-27

Source: Longer - Nut Processing Solution Provider

Source: Longer - Nut Processing Solution Provider