Our page uses cookies

We use cookies to personalize and enhance your browsing experience on our website. By clicking "Accept All", you agree to use cookies. You can read our Cookie Policy for more information.

LFM - Nuts Processing Solution Provider

86 18538579801

EN

EN

| Model | LGZ60*50*100 | LGZ90*80*110 |

| Output | 20-30t/h | 35-55t/h |

| Power | 4kw | 5.5kw |

| Voltage | 380v | 380v |

Industrial Cocoa Bean Grinding Machine Supplier Small Scale

Commercial Eletric Nut Chopper for Almond Macadamia

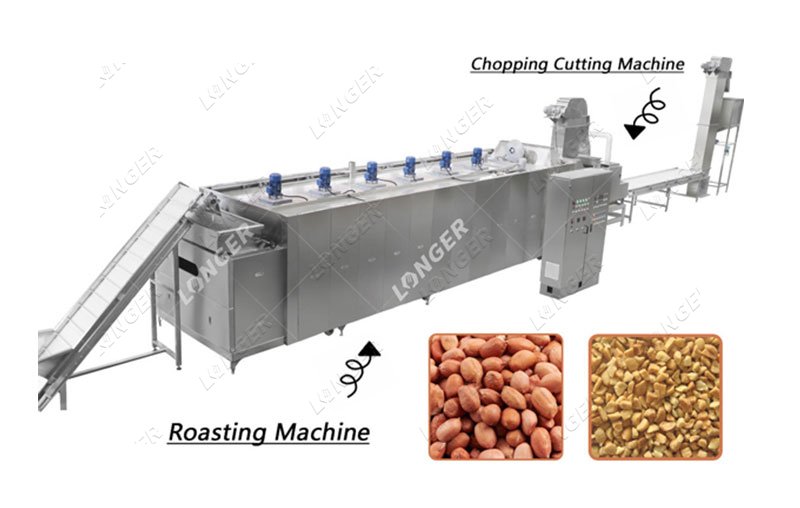

500KG/H Peanut Roasting Chopping Production Line Factory Price

Cocoa Bean Dehulling Machine Cocoa Splitting Machine

We use cookies to personalize and enhance your browsing experience on our website. By clicking "Accept All", you agree to use cookies. You can read our Cookie Policy for more information.